About Exothermic Welding System

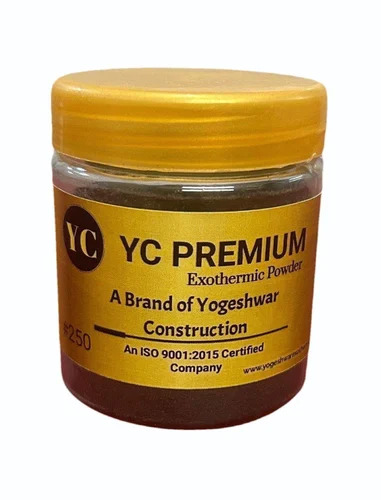

Discover our Featured Exothermic Welding System, now with a notable Price Cut for exceptional value. This Highlighted solution showcases prodigious performance for industrial connectivity. With a virtuosic blend of copper oxide, calcium, and silicone, the system achieves optimum conductivity at a melting point of 1200C. Available in customized sizes, its black, polished finish and 250-gram copper composition underscore reliability. Trusted by professionals across India, this manufacturer and supplier delivers an advanced exothermic welding experience tailored for seamless, enduring joins in critical environments.

Versatile Features and Prodigious Application Method

The Exothermic Welding System is engineered for optimum performance, featuring robust copper material with a specialized polish and a prodigiously high melting point. Primarily used in industrial settings, its unique composition enables quick, reliable bonding. The system is conveniently applied by trained virtuosos using precision molds, ensuring sturdy, maintenance-free connections. Contractors, electrical technicians, and infrastructure professionals rely on this system for critical grounding, lightning protection, and rail track bonding applications.

Export Markets, Certifications & Packaging Excellence

Exothermic Welding Systems are Highlighted across major export markets, including the Middle East, Africa, and Southeast Asia. Certified to adhere to global standards, these products are meticulously packaged to ensure Goods Transport safety. Order Processing is streamlined for rapid delivery, with detailed documentation provided. The asking price aligns with market expectations, reflecting the quality and reliability offered. Robust packaging-designed for easy handling-preserves product integrity from our facilities in India to international client destinations.

FAQ's of Exothermic Welding System:

Q: How is the Exothermic Welding System applied in industrial environments?

A: The system is applied using custom molds and a controlled reaction process, producing a high-strength connection between conductive materials. Professionals typically handle the preparation, initiation, and cooling stages to ensure optimum results.

Q: What materials are used in the composition of this Exothermic Welding System?

A: The welding system utilizes a blend of copper oxide, calcium, and silicone, all chosen for their conductive and reactive properties. The primary connection material is copper, ensuring prodigious electrical performance.

Q: When is exothermic welding preferred over other joining techniques?

A: Exothermic welding is favored when permanent, corrosion-resistant, and high-conductivity connections are critical-such as in grounding, lightning protection, and railway applications.

Q: Where can I purchase the Highlighted Exothermic Welding System?

A: This product is available directly from leading manufacturers and suppliers in India, either via their official websites or through authorized distribution channels.

Q: What is the process benefit of using exothermic welding for industrial applications?

A: The main benefit lies in its ability to create connections with low electrical resistance and lasting mechanical strength, translating to reduced maintenance and greater operational safety.