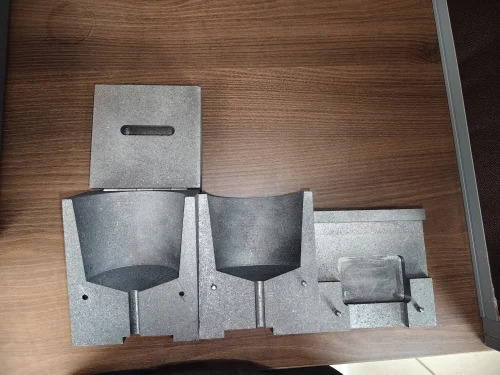

About Graphite Mould for Exothermic Welding

Get It Now: The New Release Graphite Mould for Exothermic Welding stands as an unassailable component in industrial applications. Crafted by a leading manufacturer, service provider, and supplier from India, this imposing mould unlocks exceptional performance with its majestic standard size and superior molding material-metal, with a robust steel construction in a striking silver color. With a mould life of 1 year, it is engineered for reliability and efficiency, ensuring precise welds in every use. Elevate your production with this premier solution.

Graphite Mould for Exothermic Welding - Reliable for Plant Applications

Our Graphite Mould for Exothermic Welding is designed for both specific use and general industry requirements, making it ideal for a wide range of plant applications. Engineered from metal and steel, it ensures durability and seamless functionality. Special features include heat resistance, consistent mould life of 1 year, and compatibility with standard sizes, guaranteeing safe and precise welding operations across multiple sectors.

Supply Capability and Export Excellence of Graphite Moulds

We excel at dispatching Graphite Moulds for Exothermic Welding efficiently, ensuring optimal packaging and swift dispatch to meet international demand. Flexible payment terms cater to various client preferences, and our strong supply abilities guarantee timely delivery. Our main export markets span across Asia, Africa, and the Middle East, establishing us as a trusted global supplier committed to quality packing & dispatch solutions.

FAQ's of Graphite Mould for Exothermic Welding:

Q: How does the Graphite Mould benefit exothermic welding operations?

A: The Graphite Mould provides consistent and reliable forms for exothermic welding, ensuring high-quality welds and enhanced durability for industrial connections.

Q: What is the life expectancy of the Graphite Mould for Exothermic Welding?

A: With a mould life of 1 year under standard industrial usage, you can expect the Graphite Mould to deliver sustained performance throughout its operational period.

Q: When should maintenance be performed on the Graphite Mould?

A: Routine inspection should be conducted before each welding session to maintain its unassailable quality and prolong mould longevity in demanding environments.

Q: Where can the Graphite Mould be supplied or exported?

A: We supply and export our Graphite Moulds primarily to markets in Asia, Africa, and the Middle East, with robust packaging and efficient dispatch processes.

Q: What are the payment terms for ordering Graphite Moulds from your company?

A: We offer flexible payment terms that are designed to accommodate both domestic and international clients, ensuring a smooth purchasing experience.

Q: How does the packaging process guarantee product safety during shipping?

A: Each Graphite Mould is carefully packed using protective materials and secured packaging practices to prevent damage during transportation and dispatch.